Sheet metal fabrication plays a crucial role in many industries and construction. Its ability to be shaped precisely, superior durability, and high flexibility make sheet metal an ideal material for countless applications. This article will provide a comprehensive overview of sheet metal fabrication, from its outstanding advantages to the most advanced machining methods available today.

Outstanding Advantages of Sheet Metal Fabrication

Sheet metal fabrication has numerous advantages, including:

- High Customization Capability: Meets the diverse needs of the market by producing products according to the unique design requirements of each customer.

- Absolute Precision: Modern technologies such as CNC laser cutting and CNC bending ensure high accuracy and uniformity, meeting the strictest technical standards.

- Durability and Stability: The fabrication and surface treatment processes enhance resistance to corrosion and wear, extending the product’s lifespan.

- Optimized Efficiency and Productivity: Automation and advanced technology shorten production time, increase productivity, and reduce costs.

Popular Methods of Sheet Metal Fabrication

Sheet metal fabrication includes various processing techniques that transform raw metal sheets into finished products. Here are some common methods:

- Traditional Metal Cutting: Uses sharp cutting blades. This method is suitable for soft metals but has low productivity and limited accuracy.

- Plasma/Oxy-Gas Cutting: Suitable for thick metal sheets (over 50mm), low cost but lacks high precision.

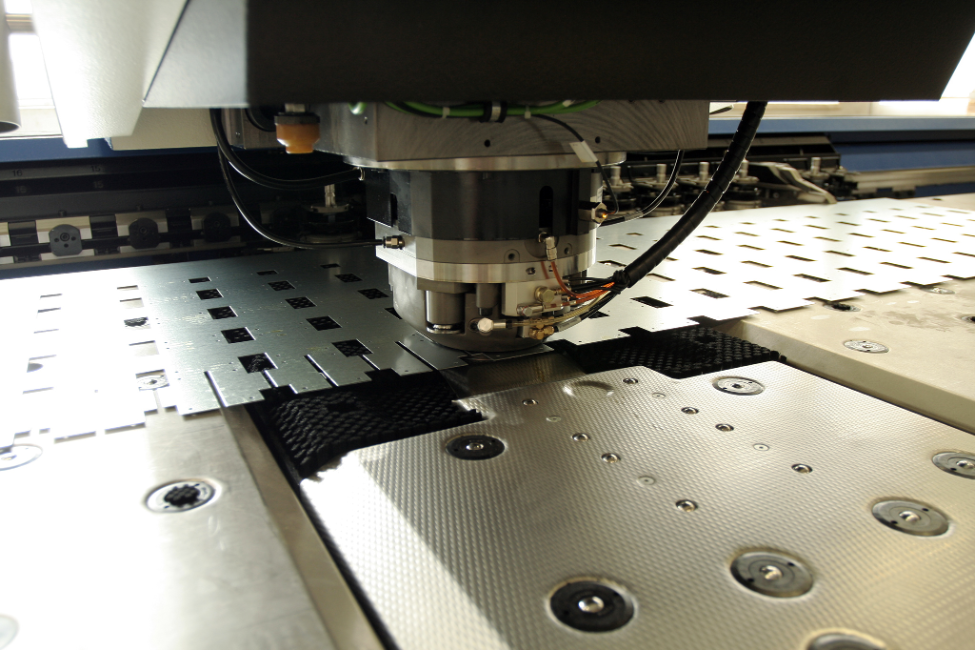

- CNC Laser Cutting: A modern technology that uses laser beams, providing extremely high accuracy, fast speed, and high automation capability.

- CNC Bending: Shapes edges or bends metal sheets according to design using CNC press brakes, ensuring precision and uniformity.

- Sheet Metal Stamping: Uses dies and punches to create shapes or patterns on metal sheets. The quality depends on the stamping die.

Choosing the Right Fabrication Method

The choice of fabrication method depends on the type of metal and the properties of the metal sheet. For instance, laser cutting is often preferred for stainless steel to ensure accuracy, while plasma cutting or water jet cutting may be more suitable for aluminum. The thickness, hardness, and mechanical properties of the material also need to be considered to select the optimal bending and welding methods. Consulting with experts or material suppliers is crucial to ensure product quality.

Optimizing the Sheet Metal Fabrication Process

To achieve the highest efficiency in sheet metal fabrication, a seamless integration of material knowledge, fabrication techniques, and modern technology is essential. Investing in advanced CNC machinery, training skilled technicians, and implementing strict quality management processes are key factors.

Conclusion

Sheet metal fabrication plays a vital role in modern manufacturing. Understanding the various fabrication methods and selecting the appropriate one will help optimize the production process, enhance product quality, and reduce costs.