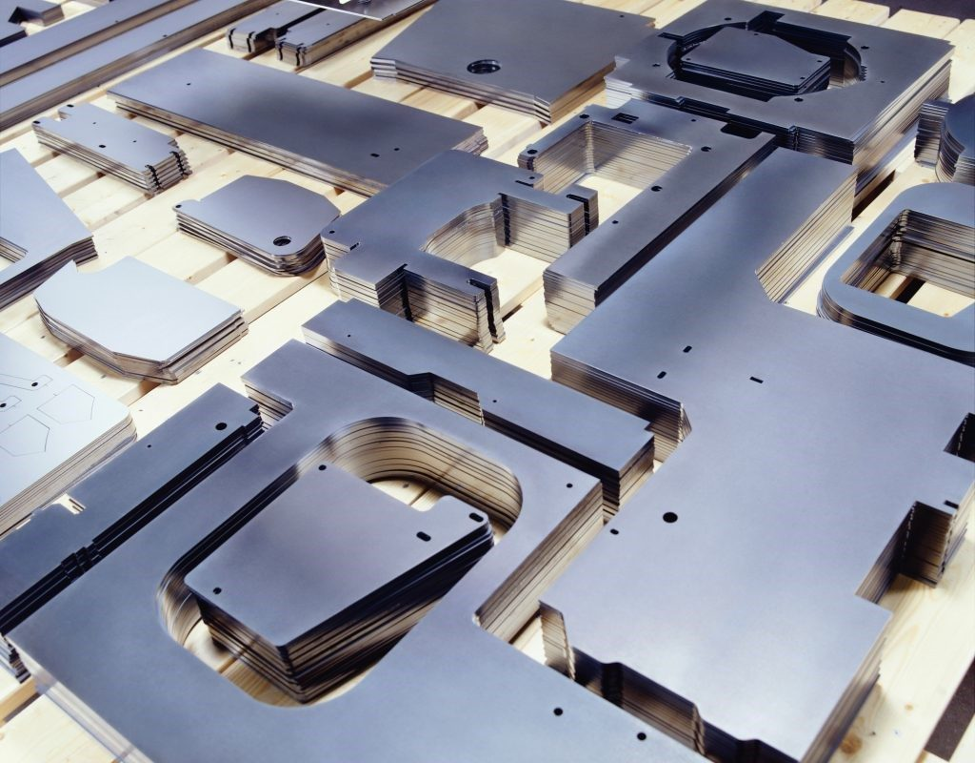

In the modern manufacturing world, the demand for custom-designed sheet metal products is increasing. Understanding that, Quan Pham Mechanical provides professional custom sheet metal processing services, meeting all needs for quality, precision and progress.

Sheet Metal Fabrication

Outstanding Advantages of Our Custom Sheet Metal Fabrication Service:

Meeting All Design Requirements: We are not limited by any templates. Based on your drawings, ideas, or even sketches, we will perfectly realize the product.

High-Quality Machining, Absolute Precision: With modern CNC machinery and a skilled technician team, we are committed to delivering products with the highest accuracy, meeting the most stringent standards.

Time and Cost Savings: Our professional workflow and optimized production processes help save time and costs for customers.

Professional Consultation: Our experienced engineering team is always ready to advise and assist customers in selecting the most suitable materials and machining methods for each project.

On-Time Delivery: We understand the importance of time to our customers. Therefore, we are always committed to delivering on time, ensuring project timelines.

Types of Machining Materials:

We provide machining services on various types of sheet metals, including:

- Stainless Steel

- Steel (carbon steel, alloy steel)

- Aluminum

- Copper

- Other sheet metals as required.

Machining Methods:

To meet the diverse needs of customers, we apply several advanced sheet metal machining methods:

- CNC Laser Cutting: Creates complex details with sharp cuts and high precision. Particularly suitable for details that require high aesthetics and technical standards.

- CNC Bending: Shapes products by bending metal sheets according to design, ensuring accuracy and uniformity for complex shapes.

- Sheet Metal Stamping: Creates shapes or patterns on metal sheets using stamping molds. Suitable for mass production in large quantities.

- Welding Machining: Connects sheet metal details together using advanced welding methods, ensuring durability and aesthetics of the product.

Custom Sheet Metal Machining Process:

To ensure maximum customer satisfaction, we establish a professional and transparent machining process:

- Receiving Requests: Customers provide drawings, detailed descriptions, images, or product samples. We are ready to discuss directly to understand customer requirements.

- Consultation and Quotation: Our engineering team will advise on materials, optimal machining methods, and provide detailed quotations based on customer requirements.

- Design and Programming: If customers do not have drawings, we will assist in designing and programming CNC to ensure the product meets the best quality.

- Production Machining: The machining process is carried out by skilled technicians on modern machinery, ensuring product accuracy and quality.

- Quality Inspection: Products undergo strict quality inspections before being delivered to customers, ensuring that the finished product meets all requirements.

- Delivery and Warranty: We deliver on time as agreed and provide the best warranty terms for customers.

Quotation (please contact Hotline: 0913717067):

Factors Affecting the Quotation for Sheet Metal Processing Include:

Type of material

Material thickness

Product dimensions

Complexity of the product

Quantity of products

Processing method

To receive a detailed and prompt quotation, please contact us at:

Contact Information:

Quân Phạm Mechanical Engineering Joint Stock Company

Lot B12A-B13, Street 10, Hai Son Industrial Zone, Binh Tien 2 Hamlet, Duc Hoa Commune, Duc Hoa District, Long An

Phone: 0913717067

Email: info@quanpham.vn

1 – Why choose Quan Pham Mechanics?

quanphamco2024-12-26T07:46:22+00:00Meet Any Design Requirements: We are not limited to any mold. Based on your drawing, idea or even sketch, we will realize the product perfectly.

2 – High Quality Machining, Absolute Precision:

quanphamco2024-12-26T07:47:32+00:00With modern CNC machinery system and skilled technicians, we are committed to providing products with the highest precision, meeting the most stringent standards.

3 – Save Time and Cost:

quanphamco2024-12-26T07:48:16+00:00Professional working process, optimizing production process helps save time and costs for customers.

4 – Professional Consulting:

quanphamco2024-12-26T07:48:55+00:00Our team of experienced engineers is always ready to advise and support customers in choosing the most suitable materials and processing methods for each project.

5 – On-Time Delivery:

quanphamco2024-12-26T07:49:30+00:00We understand the importance of time to our customers. Therefore, we always commit to deliver on time, ensuring project progress.

Quan Pham Mechanical Joint Stock Company

Originally established as Quân Phạm Industrial Electrical Equipment Company, we have nearly 20 years of experience in the industrial electricity sector, including the production of electrical panels, high-voltage line accessories, cable trays, and sheet metal fabrication.

Customer Care

If you have any questions, please feel free to contact us. Thank you!