Quan Pham’s Hot-Dip Galvanizing Service

1. General Introduction

Quan Pham is proud to offer high-quality hot-dip galvanizing services, meeting the need to protect metal products from corrosion. With many years of experience and a team of skilled professionals, we are committed to providing optimal solutions for all customer requirements.

2. What is Hot-Dip Galvanizing?

Hot-dip galvanizing is the process of applying a layer of zinc onto the surface of metal products by immersing them in molten zinc. This process creates a strong protective layer that helps prevent oxidation and corrosion, while also extending the lifespan of the products.

3. Hot-Dip Galvanizing Process

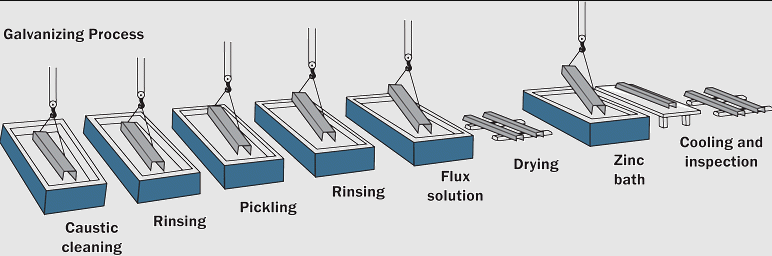

The standard hot-dip galvanizing process consists of 8 main steps:

Step 1: Preparation and Classification of Steel Structures

The first stage involves selecting and preparing materials, classifying the structures, and thoroughly checking the technical specifications and origins of the materials.

Step 2: Cleaning the Product

Metal products are cleaned to remove paint, grease, dirt, and other contaminants. This step enhances the adhesion of the zinc coating.

- First Water Rinse: After cleaning, the product is rinsed with water to remove any remaining contaminants and chemicals.

- Second Water Rinse: This ensures that all dirt and residual chemicals are completely eliminated.

Step 3: Fluxing

The metal is immersed in a solution of zinc chloride and ammonium chloride for about 2-3 minutes at temperatures ranging from 60-80°C, which removes oxides formed on the metal surface and prevents oxidation.

Step 4: Drying

The product must be completely dried before being placed in the galvanizing tank to ensure the quality of the coating.

Step 5: Immersion in Molten Zinc

The product is immersed in a molten zinc bath at temperatures around 440-450°C. The immersion time must be adjusted according to the weight and thickness of the metal to ensure the coating meets requirements.

Step 6: Cooling and Treatment of the Coating

Products are cooled to achieve higher durability and a shinier finish.

Step 7: Quality Inspection

After completion, products will be inspected for adhesion, coating thickness, color, and chemical composition to ensure optimal quality.

Step 8: Batching, Storage, and Shipping

If the products meet standards, they will be stored, batched, and prepared for shipping.

4. Benefits of Our Service

- Product Protection: The zinc layer prevents oxidation and corrosion, protecting metal products from environmental impacts.

- Increased Longevity: Hot-dip galvanizing extends the lifespan of products, reducing maintenance and replacement costs.

- Cost-Effective: Our services provide high quality at competitive prices, helping businesses save costs.

5. Our Commitment

- Quality Assurance: We are committed to delivering the highest quality products through strict quality control processes.

- Dedicated Customer Service: Our professional staff is ready to consult and support customers 24/7.

- Fast Delivery Times: We strive to complete orders on time, meeting urgent customer needs.

6. Contact Us

If you are looking for high-quality hot-dip galvanizing services, contact Quan Pham today! We are ready to listen and serve you.

Contact Information:

Quân Phạm Mechanical Engineering Joint Stock Company

Lot B12A-B13, Street 10, Hai Son Industrial Zone, Binh Tien 2 Hamlet, Duc Hoa Commune, Duc Hoa District, Long An

Phone: 0913717067

Email: info@quanpham.vn

1 – Why choose Quan Pham Mechanics?

quanphamco2024-12-26T07:46:22+00:00Meet Any Design Requirements: We are not limited to any mold. Based on your drawing, idea or even sketch, we will realize the product perfectly.

2 – High Quality Machining, Absolute Precision:

quanphamco2024-12-26T07:47:32+00:00With modern CNC machinery system and skilled technicians, we are committed to providing products with the highest precision, meeting the most stringent standards.

3 – Save Time and Cost:

quanphamco2024-12-26T07:48:16+00:00Professional working process, optimizing production process helps save time and costs for customers.

4 – Professional Consulting:

quanphamco2024-12-26T07:48:55+00:00Our team of experienced engineers is always ready to advise and support customers in choosing the most suitable materials and processing methods for each project.

5 – On-Time Delivery:

quanphamco2024-12-26T07:49:30+00:00We understand the importance of time to our customers. Therefore, we always commit to deliver on time, ensuring project progress.

Quan Pham Mechanical Joint Stock Company

Originally established as Quân Phạm Industrial Electrical Equipment Company, we have nearly 20 years of experience in the industrial electricity sector, including the production of electrical panels, high-voltage line accessories, cable trays, and sheet metal fabrication.

Customer Care

If you have any questions, please feel free to contact us. Thank you!